Elemental Insights to Elevate Your Science

Connect Your Operations to Secure Your Outcomes

At Elemental Machines, we're redefining connectivity in laboratory and manufacturing spaces. Our seamlessly integrated hardware, software, and data science solutions continuously transmit data from your environment to the cloud and onto your personalized dashboard. With our watchful eye monitoring your ecosystem around the clock, we ensure the integrity and efficiency of your operations.

Unparalleled Connectivity at the Heart of Your Operations

Embrace the future of IoT in labs and manufacturing with Elemental Machines. Our state-of-the-art connectivity solutions are designed to keep you ahead of the curve, enabling real-time monitoring and management of your entire ecosystem. Incorporating predictive analytics, our platform transforms complex data into digestible information, allowing you to anticipate and address issues before they arise, ensuring a proactive operational approach and keeping you aligned with GxP compliance standards.

See More

Every Asset

Our system connects nearly any piece of equipment, from any manufacturer or era.

Every Metric

Monitor usage, temperature, humidity, light, vibration, and more.

Anywhere

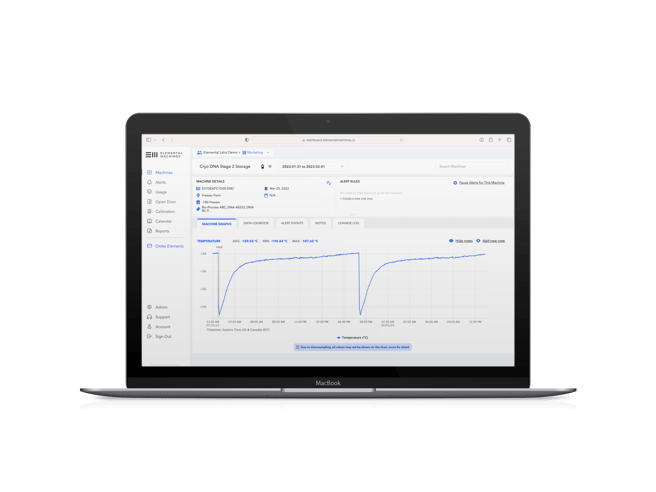

Our cloud-connected dashboard connects you to your data anywhere in the world.

Anytime

Continuous monitoring 24/7 never takes a day off — so you finally can.

Custom Integrations for Connected Labs and Manufacturing Facilities

Our platform thrives on flexibility and adaptability, offering custom integrations that seamlessly mesh with your existing infrastructure. Whether in the lab or on the manufacturing floor, Elemental Machines’ technology scales with your organization, growing from incubator to enterprise, ensuring a tailored fit every step of the way.

Implementation:

It Doesn’t Get Any Easier

Than This

Implementation of your Elemental Machines solutions are fast and easy, designed to integrate effortlessly with your current systems. Less than a minute after unboxing, data starts flowing into your personalized dashboard. Experience how our intelligent lab and manufacturing IoT solutions can transform your operations, offering ease of installation and sophistication in performance.

Simple, Intelligent, Connected

Simplicity

Our solutions are designed for effortless integration and user-friendly operation. From easy installation to intuitive dashboards, we streamline your workflows and facilitate automation, making complex data management feel simple and accessible.

Intelligence

Powered by advanced data science, our platform offers smart, data-driven insights. With predictive analytics and automated alerts, we turn vast amounts of data into actionable information, enabling you to make informed decisions swiftly.

Connectivity

At Elemental Machines, connectivity is key. Our systems ensure seamless communication with your lab and manufacturing equipment, creating a cohesive and fully integrated operational network that enhances collaboration and efficiency.

Grow With Us:

Scalable Solutions Aligned With Your Ambitions

As your organization evolves, so do our solutions. Our commitment to scalability means that as you grow from a small incubator to a large enterprise, an R&D lab to GMP manufacturing, or anything in between, Elemental Machines’ solutions grow with you.

We provide consistent support and advanced solutions tailored to your expanding needs. This ensures seamless scalability for your operations — not just in capacity, but also in rigorous lab and manufacturing quality control, ensuring your ability to maintain GxP compliance as your organization grows.

Discover the Future of

Interconnected Operations

With Elemental Machines

Where every connection leads to new possibilities

and every insight propels you forward.